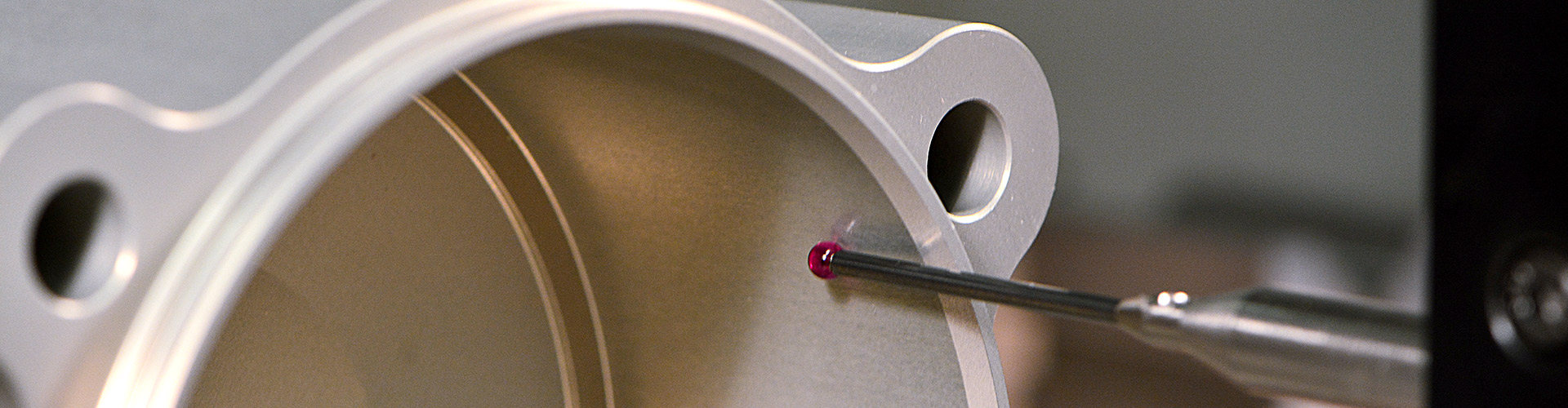

A key component to our Quality Control Program is the inspection and documentation of the product being produced. JCB Precision continues to make serious investments in high accuracy metrology equipment and measurement capabilities.

Selection of Measuring Equipment

We will evaluate a component to determine the best inspection method for each feature, and then add it to the part’s documentation. If we don’t have a tool that we need, it will be acquired. Some examples of our selection of inspection methods include:

- Threads are measured with ground thread plugs or rings

- Internal diameters are measured with digital bore gages with .00001 resolution

- Feature locations are measured on a Mitutoyo comparator or digital height gage

- Outside features are measured with .0001” resolution micrometers

- Visual inspections are performed under 3x – 10x magnification

JCB Precision is here to make the best parts possible and we know how important it is to have the right tools for the job.

Learn more information about the types of measuring equipment.

Gage Maintenance Program

Inspection equipment and gaging are assigned unique serial numbers and controlled through a gage maintenance program. All gaging is calibrated and traceable to NIST standards. Annual gage calibrations are performed by an external, independent metrology lab.

Inspection Reports

Inspection Reports are created for each part. The report lists each feature, dimension, and tolerances that need to be inspected. For key or tight tolerance features, the inspection report has an SPC style plotting sheet that we use to record measurements with a high frequency of inspection. Reports are made available to the customer and included with the shipment.

In Process Inspection

First piece inspections are performed on all parts. The first piece consists of 100% inspection of features created at a specific operation, and is documented on the inspection report. Following the first piece inspection, the part receives in-process inspections to insure that the part remains conformant to print and that the process is stable throughout the operation.

Component inspection and metrology is an extremely important element to producing high quality products. Equally important is the Procedures and Systems that a manufacturer uses throughout the entire process.

Read more about our Process Control.