Below are examples of solutions we’ve provided for our customers.

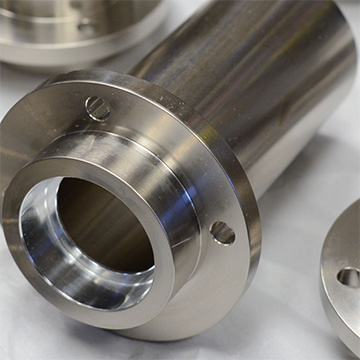

Tight Geometric Tolerances

We are able to provide our customers solutions to challenging and critical components. The geometric features in this example were held to less than +/-.000070.

Our customer needed a precision machined part with tight geometric tolerances. It consisted of 2 opposing tight tolerance bores. The part needed to be Nickel plated with exception to the bores, however the ID between the two critical bores also needed plating.

Bore Diameters: +/-.0001″

Roundness: .0003″ Max

Concentricity: .0003″ Max

Cylindricity: .0003″ Max

Surface Finish: 16Ra Max

The process for this part allowed minimal flexibility. Precision work holding was designed and made. Variables that impact the part’s dimensional stability were identified and eliminated. JCB Engineering designed special plugs to mask the sensitive bores during plating and successfully allowed the inner ID to be plated.

All in house inspections yielded dimensions that were in specification. Due to the critical nature of the component, the parts were also sent to an outside source for secondary verification. The original results were supported.